PET Preform for Cans and Jars

PET is short of polyethylene terephthalate, a thermoplastic material with wide applications.

1. Good mechanical properties, the impact strength is 3-5 times of other films.

2. Resistant to oil, fat, dilute acid and alkali, and most solvents.

3. Excellent resistance to high and low temperature, working well under 70 ℃ to 120 ℃. The temperature impacts its mechanical properties tiny.

4. Low gas and water vapor permeability.

5. High transparency, good UV blocking and glossiness.

6. Non-toxic and smell less, used directly for food packaging.

Therefore, PET is very suitable for making food bottles, such as oil, water, soft drink and alcoholic beverages.

We have many years professional experience in PET preforms production. Before producing preforms, we use reasonable temperature to dry pet raw materials.

It reduces the water content then improves the viscosity IV, but not increases acetaldehyde AA.

We use PET special screw, with compression ratio 1.6:1, and the length diameter ratio 24:1.

Manipulator + conveyor belt system are used to avoid damage to preforms.

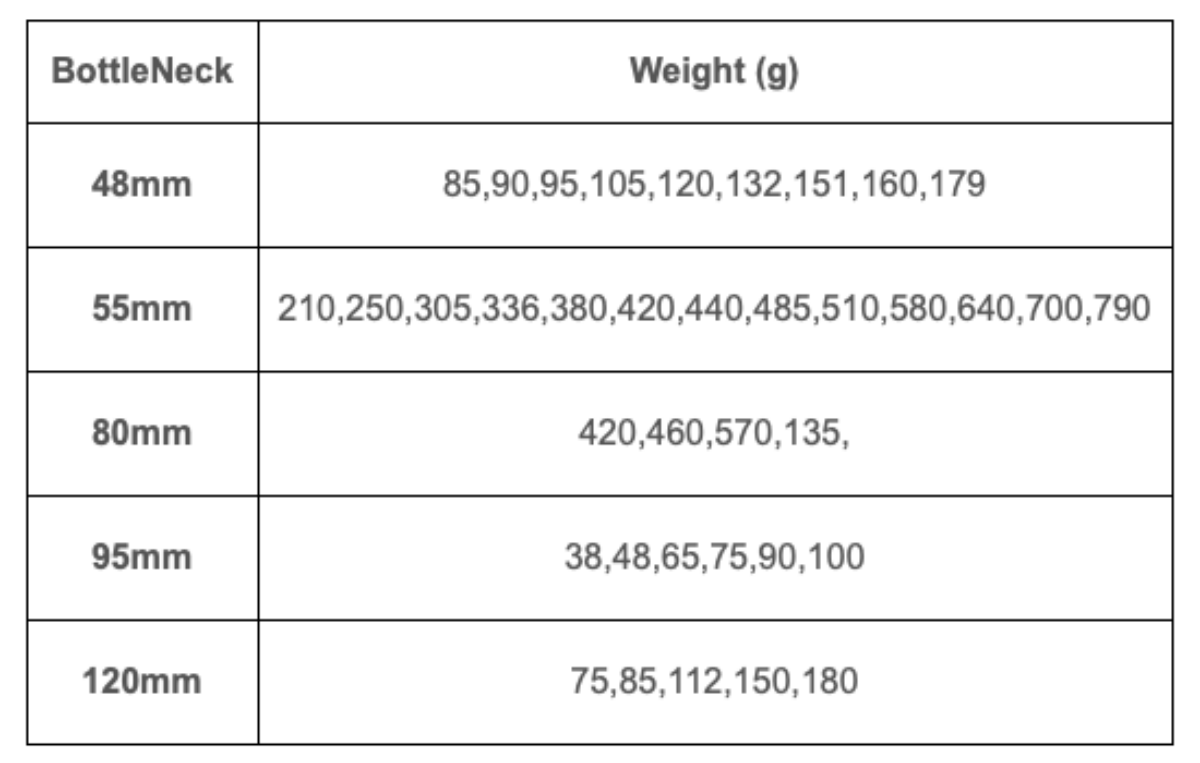

There are dozens of preforms for choice, with different diameter and weight.

The bottleneck above 48mm, are used for jars, large barrels water.

Q1: What’s your product range?

A: 1. PET preforms are from 45g to 275g.

2. We also have the ABS/PP Caps match the preforms.

Q2: Are you a manufacturer?

A: Yes,we have been in producing PET preform and caps for many years.

Q3: What information should I let you know if I want to get a quotation?

A: The weight and bottleneck of the preforms you need.

Q4: Do you offer free samples?

A: Yes,we supply free samples, only ask freight collected.

Q5: How many days will samples be finished?And how about the mass production?

A: 1. Usually, 3-5 days for sample making.

2. Usually 15-20 days for mass production.